“Webbing” is a term you’ll encounter across countless industries, from sailing and automotive to apparel and industrial manufacturing. But what exactly is webbing, and why is it so prevalent?

At its core, webbing is a strong, woven fabric typically made from materials like cotton, nylon, polyester, or polypropylene, and is used for its durability, flexibility, and high tensile strength. It is commonly produced in flat or tubular form and comes in various widths and thicknesses.

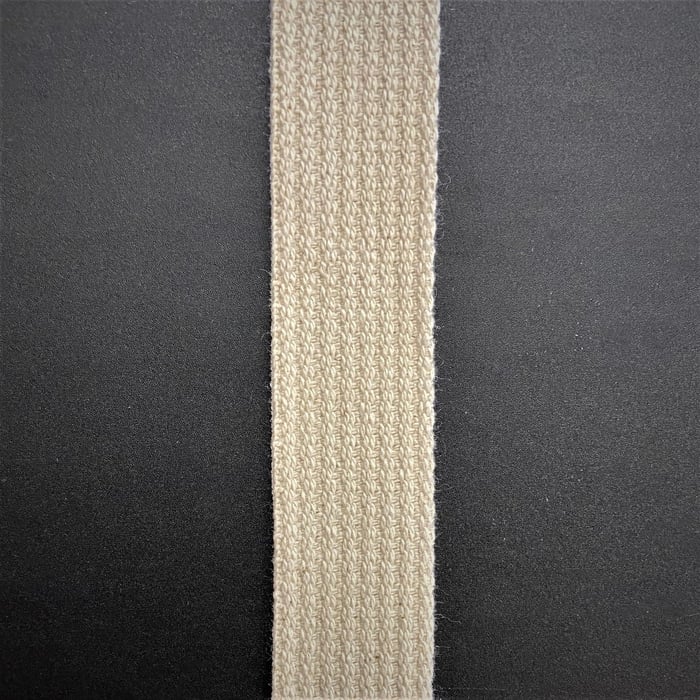

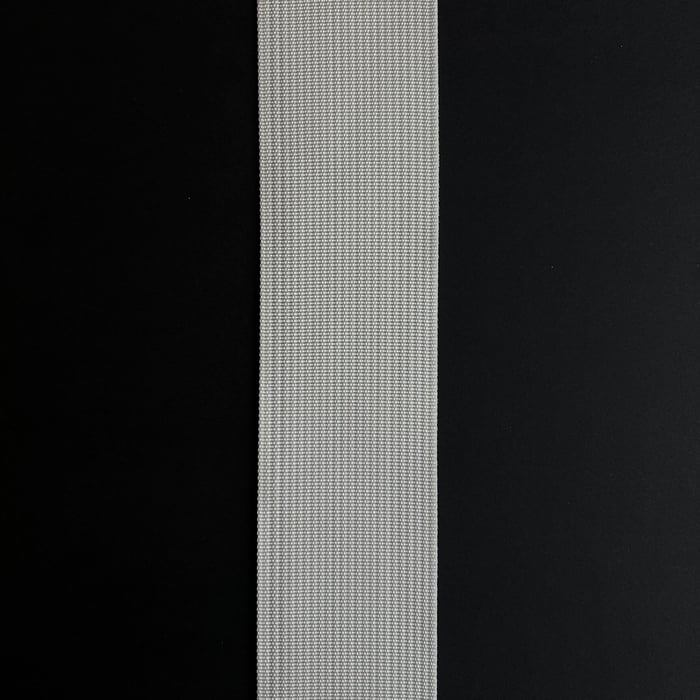

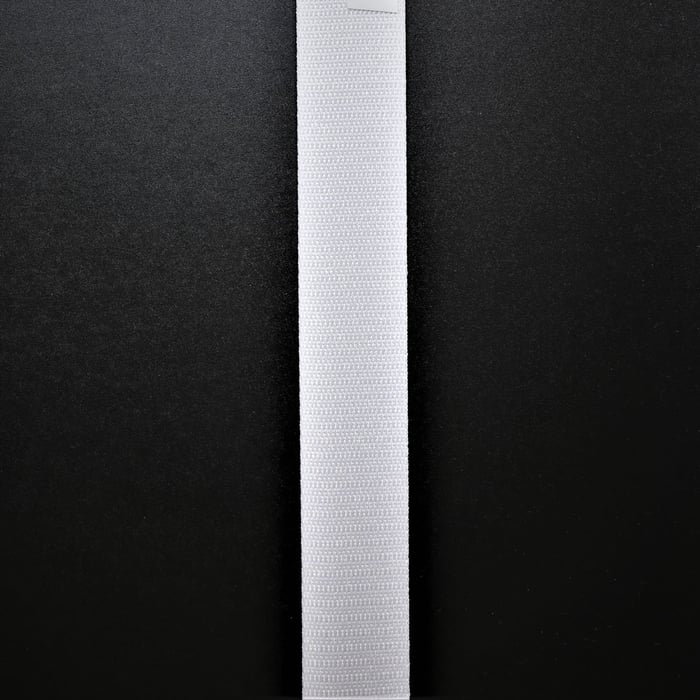

Woven webbing is created on narrow fabric looms, such as needle looms or shuttle looms, using warp (lengthwise) and weft (crosswise) yarns. Common weaves include plain, twill, and herringbone.

Key Characteristics

- High Tensile Strength

- Dimensional Stability

- Flexibility

- Durability

Types of Webbing

The versatility of webbing stems from the wide variety of materials and construction methods used to create it. Here’s a breakdown of the most common types:

- Nylon: Arguably the most popular, nylon webbing is known for its exceptional strength, abrasion resistance, and resistance to chemicals and UV degradation. It’s frequently used in backpacks, belts, and outdoor gear.

- Polyester: A strong contender, polyester webbing offers excellent UV resistance, making it ideal for applications exposed to sunlight. It’s also known for its resistance to mildew and chemicals.

- Cotton: While not as durable as nylon or polyester, cotton webbing remains a viable option for applications where aesthetics or a more natural feel are prioritized. Often used in canvas bags and certain apparel applications.

- Polypropylene: This lightweight and cost-effective option is resistant to water and chemicals, making it suitable for outdoor and industrial applications.

Common Applications of Webbing

Webbing’s robust nature and adaptability make it a vital component in a vast array of industries:

- Apparel: Backpacks, belts, handbags, shoes.

- Nylon: Dominates backpacks and belts due to its strength, abrasion resistance, and durability. Common for straps and adjustable components.

- Polyester: Increasingly used in handbags and shoe components for its UV resistance and often softer feel compared to nylon.

- Cotton Webbing: Found in canvas bags and some footwear for a more natural aesthetic, though it offers less strength and durability.

- Automotive: Seatbelts, interior trim, cargo restraints.

- Nylon: The primary material for seatbelts due to its high strength, elasticity, and ability to withstand significant stresses.

- Polyester: Utilized in interior trim and cargo restraints for its durability, UV resistance, and resistance to chemicals found in vehicle environments.

- Marine: Sailcloth, boat covers, rigging.

- Nylon: A longstanding choice for sailcloth and boat covers due to its strength, resistance to saltwater, and ability to handle extreme weather conditions.

- Polyester: Gaining popularity in boat covers for its enhanced UV resistance and durability.

- Industrial: Strapping, conveyor belts, safety equipment.

- Nylon: A versatile choice for various industrial applications, including strapping, conveyor belts, and safety equipment, thanks to its strength and abrasion resistance.

- Polypropylene: Used in conveyor belts for its lightweight properties and resistance to chemicals and moisture.

- Outdoor Gear: Tents, tarps, backpacks.

- Nylon: Remains a popular choice for tents and tarps due to its strength, durability, and resistance to weather elements.

- Polyester: Increasingly favored for tarps due to its superior UV resistance.

Choosing the Right Webbing Material

Selecting the appropriate webbing material is important for ensuring its effectiveness and longevity. Here are key factors to consider:

- Load-Bearing Capacity: Determine the maximum weight the webbing needs to support, factoring in both static and dynamic loads. Always apply a safety factor (typically 2-4) to account for unexpected forces. Webbing construction (weave patterns) significantly impacts strength.

- Environmental Conditions: Webbing’s performance is influenced by its operating environment. Consider:

- Sunlight Exposure: UV radiation degrades materials like nylon and polyester. Polyester offers superior UV resistance; consider UV stabilizers for nylon.

- Chemical Exposure: Polypropylene is highly resistant to chemicals. Nylon is susceptible to solvents and acids.

- Moisture & Temperature: Moisture weakens webbing; temperature extremes can make it brittle.

- Desired Aesthetic: The webbing's appearance matters. Consider color, texture (weave patterns), and finish (matte, glossy).

- Cost: Balance performance with your budget. Higher-quality webbing (e.g., nylon, polyester) is often more expensive but can reduce long-term replacement costs and downtime. Carefully assess the overall lifecycle cost.

Wayne Mills: Your Webbing Solutions Partner

At Wayne Mills, we specialize in providing high-quality webbing products to meet your unique needs. We offer a comprehensive selection of webbing materials, along with expert advice to help you choose the perfect webbing for your application.

Contact us today to receive a personalized quote.

Popular Webbing Products